Department remelts plastic waste into chairs

A ton of plastic. This is how much plastic waste is generated in the course of a year at the Department of Molecular Biology and Genetics. The plastic comes, among other things, from plastic boxes containing pipettes. Previously, the plastic was thrown away, but now three employees have had the idea to melt it into chairs.

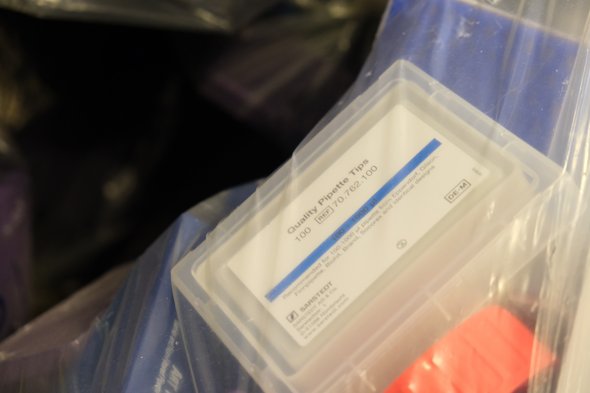

During the corona shutdown, the employees at the department collected plastic waste from the laboratories. And this quickly turns into a lot of plastic. In fact, a whole ton in one year. The plastic comes, among other things, from boxes with pipette tips and other remedies used in laboratories.

Anette Kjems, who is a laboratory technician and purchasing coordinator at the department, says that in a week of student exercises in the laboratory, they can easily fill two large plastic bags with boxes from pipette tips. There are 96 in each box.

Engineering assistant Henrik Hartvig Kolmos adds: "We asked ourselves: How much plastic waste do we really have? Before, we all threw the plastic into a container. It was only when we started collecting together and calculating how much we threw away that the idea of recycling the plastic made sense.”

The plastic forms part of a cycle

Although the employees at the department have so far sorted the plastic according to different types of plastic, it has not been clear what happened to the plastic after it ended up in the bin. A committee set out to find out.

"I was very surprised at how far we have come in Denmark when it comes to recycling plastic. It's a whole life cycle. You can see where it is collected and where it can be used again. It's a whole new world," says laboratory technician Anna Marie Nielsen, who sits on the committee.

Anna Marie Nielsen, who is a leading laboratory technician at the department and also part of the committee, discovered that at Randers Regional Hospital they used reusable plastic to make chairs, and soon the idea was discussed at the institute.

450 chairs and more sustainability

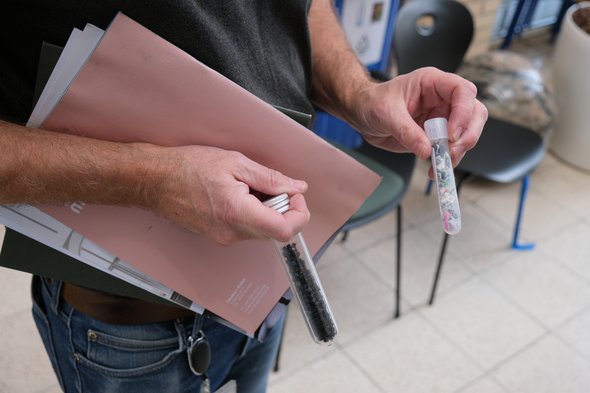

On Wednesday last week, bags of plastic were picked up at the department and shipped to Randers, where it will be remelted into canteen, office and teaching chairs, which will henceforth be found in the department's new building in the University City. The department will move into AU's new campus in January next year. The campus is empty and new furniture is needed. This led the committee to demand that the purchased furniture be made of recycled plastic. Financially, it doesn't make a big deal:

"The price is a little cheaper with our own plastic, but it is a big saving on the CO2 footprint, which is important to us," explains Anna Marie Nielsen.

This time there were 450 chairs. And hopefully more in the future. Because the department cannot use other, more sustainable, packaging because the laboratory remedies must be sterile. The plastic is of high quality. Therefore, several companies are interested in helping the department to get it set aside, and after the first collection, the commitment has not decreased:

"We think it's a really exciting project. It is good for the climate. And we are among the first at the university to think about sustainability in this way. We also want to encourage people to come and see and maybe get some inspiration," explains Anette Kjems.